Introduction: Maize starch, also known as corn starch, is a component extracted from the endosperm of the corn kernel. This is a white, odorless, and tasteless powder. It has applications across various sectors, including the food, pharmaceutical, and chemical industries. In this comprehensive overview we will understand the maize starch in detail.

What is Maize Starch? Maize starch is a type of corn starch derived from grinding corn kernels into a fine powder and isolating the starch through a meticulous wet milling process. The resulting product is a maize starch which has versatility in its application.

Manufacturing of corn starch:

Following are the steps in manufactring of corn starch:

- Cleaning and steeping: The corn kernels are cleaned to remove impurities and then steeped (soaked) in water for 30 to 48 hours, allowing them to soften and ferment slightly.

- Milling: After steeping, the softened kernels are ground to break them down into a slurry.

- Separation: The slurry is then separated into its components through centrifugation and hydrocyclones. This process separates the starch from the other components of the corn, such as protein, fiber, and germ.

- Washing and drying: The starch is washed to remove any remaining impurities and then dried to remove moisture, resulting in a fine powder known as corn starch.

- Modification (optional): Depending on its intended use, the corn starch may undergo further modification to enhance its properties, such as stability or thickening capacity.

Uses in the Food Industry:

- Thickening Agent: Corn starch contains amylose and amylopectin starches in it. It helps thickens liquid-based foods such as soups, sauces, and gravies by forming a gel-like consistency when heated.

- Stabilizer: Maize starch is used to maintain the homogeneity and prevents the phase seperation in emulsions like sauces, salad dressings which also helps to extend the shelf life.

- Binder: In processed meats and meat alternatives, corn starch acts as a binder by enhancing cohesion and texture, hence it improves the structure of products like sausages and meatballs.

- Texture Modifier: Corn starch alters the texture of baked goods by inhibiting gluten formation, resulting in tender and moist cakes, cookies, and pastries, it also enhances the crumb structure of gluten-free bread.

- Coating Agent: When used as a coating for fried foods, corn starch creates a crispy exterior while minimizing oil absorption, yielding lighter and less greasy dishes such as crispy chicken and other fried proucts.

Structure of corn starch:

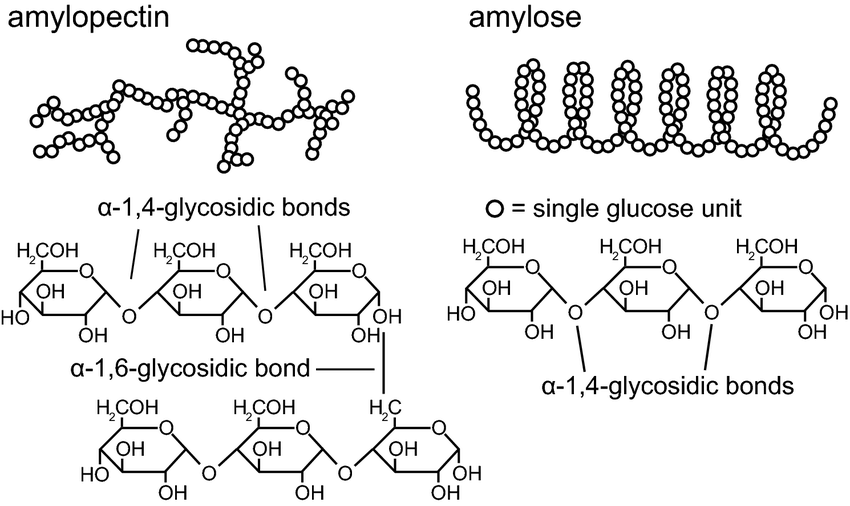

Corn starch structure is predominantly composed of two types of glucose polymers: amylose and amylopectin. Amylose forms linear chains of glucose molecules connected by alpha-1,4-glycosidic bonds, while amylopectin consists of branched chains interconnected by alpha-1,6-glycosidic bonds. This molecular arrangement results in granules with a semi-crystalline structure. Corn starch granules vary in size and shape, often irregular or polygonal, with distinct regions of crystallinity and amorphous regions.

What is Corn (Maize) Flour:

Maize flour is obtained by grinding whole corn kernels into a fine powder. The process involves milling dried corn kernels to produce a smooth texture. The resulting maize flour contains starch, fiber, protein, and a small amount of fat.

Maize flour’s high starch content provides structure and binding properties in baked goods. With its mild flavor and nutritional benefits, maize flour serves as a staple ingredient in diverse cuisines worldwide, catering to different dietary preferences and culinary needs.

| Properties | Maize Starch | Maize Flour |

|---|---|---|

| Composition | Primarily composed of amylose and amylopectin molecules extracted from corn endosperm. | Contains starch, fiber, protein, and small amount of fat, derived from ground whole corn kernels. |

| Functionality | Acts as a thickening agent, stabilizer, and binder due to gel-forming properties when heated with liquids. | Contributes to flavor, texture, and structure of baked goods, enhancing moisture content and crumb texture. |

| Gluten Content | Inherently gluten-free, suitable for gluten-sensitive individuals. | May contain gluten if cross-contaminated or blended with wheat flour, posing risk for those with gluten sensitivities. |

| Applications | Widely used in food industry, pharmaceuticals, and industrial processes for improving product consistency and stability. | Predominantly used in culinary settings for preparing traditional corn-based dishes and gluten-free baking recipes. |

Have you ever wondered how corn starch is different from which starch?

| Properties | Corn Starch | Wheat Starch |

|---|---|---|

| Source | Extracted from corn (maize) grain | Extracted from wheat grain |

| Kernel Characteristics | Derived from corn kernel | Derived from wheat kernel |

| Chemical Composition | Primarily composed of amylose and amylopectin molecules | Predominantly consists of amylose and amylopectin molecules |

| Gluten Content | Gluten-free | Contains gluten |

| Gelatinization Temperature | Gelatinizes at lower temperatures (around 60-70°C) | Gelatinizes at higher temperatures (around 75-85°C) |

| Molecular Structure | Granules are irregularly shaped and polygonal | Granules are more spherical and homogeneous in size |

Conclusion:

Corn starch, sourced from maize grain, stands as a ingredient used in food, pharmaceutical, and industrial applications. Its gluten-free composition along with distinctive gelatinization properties and chemical strucutre makes is useful in multiple industries. From thickening sauces to enhancing stability in pharmaceutical formulations, corn starch plays multifaceted roles. Its multiple application underscores its significance, contributing to texture, consistency, and nutritional profiles in diverse culinary creations.