Introduction

Tapioca starch is essentially a pure starch extracted from the cassava plant. While it may lack notable nutrients on its own, its culinary and industrial applications are boundless. But just understand what is starch in simple words!

Starch, a polymeric carbohydrate, acts as a storage form of energy in plants. It consists of glucose units bonded together, forming a chain of single sugar molecules. Starch has served various purposes, from culinary to many industrial applications.

Cassava plants are usually grown by planting small pieces of the stem in the ground. They take about 8 to 18 months to grow big roots, which come in different shapes and sizes, like cones or cylinders, and can be as big as 15 centimeters across. When you cut a cassava root, you’ll see layers inside, like the skin and the part filled with starch. It’s important to harvest the roots at the right time to get the most out of them.

These are the different shapes of Cassava:

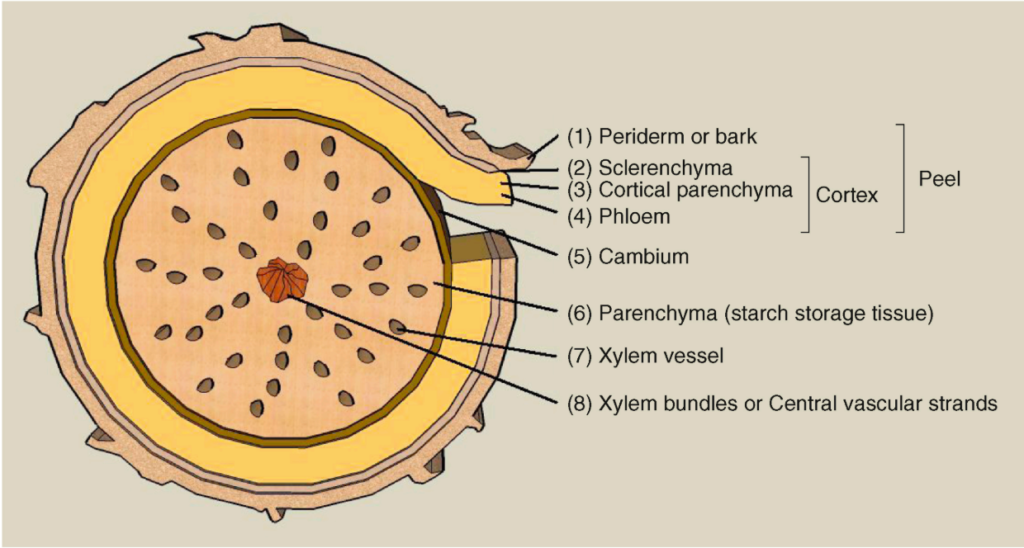

Cross section of Cassava:

Structure of Tapioca starch

Tapioca starch has a unique structural characteristics that differentiate it from cereal starches. Unlike corn and rice starches, which varies in amylose content, tapioca starch maintains a consistent amylose content of 17-20%. However, unlike other starches, tapioca amylose molecules are not entirely unbranched, as indicated by their beta-amylolysis limit, which is lower compared to cereal starches. Tapioca amylose possesses a higher molecular weight than other starches. The amylopectin structure of tapioca starch primarily consists of short chains, with a small portion of extra-long chains. Microscopic examination of tapioca starch granules shows smooth, spherical granules typically ranging from 4-35μm in diameter.

Here is how tapioca starch is modified industrially:

Tapioca starch undergoes physical, heat-moisture, chemical modifications to enhance its properties for diverse applications. Physical modification involves shear force, blending, and thermal treatment, resulting in instant (pregelatinized) starch with improved solubility. Heat-moisture treatment produces a modified starch with enhanced shear resistance and gel properties. Chemical modification includes various derivatives, such as crosslinked or hydrolyzed starches, without requiring specialized equipment. With low lipid and protein content, tapioca starch is utilized in multiple industries, benefiting from precise control of its properties through modifications, though it’s predominantly considered a specialty starch beyond its local production areas.

Nutritional information of Tapioca starch:

| Attribute | Specification |

|---|---|

| Moisture content | 13% |

| Starch content | 85% minimum |

| Ash | 0.2% |

| pH | 5.0 to 7.0 |

| Whiteness (Kett scale) | 90 |

| Viscosity (Barbender unit) | 600 |

| Sulfur dioxide content | 30 ppm |

| Cyanide content | nil |

| Appearance | White, no speck, fresh odor |

These are the applications of Tapioca starch in Food:

- Tapioca Pearls (Sabudana): Tapioca pearls, also known as sago pearls, are spherical particles made from a mixture of gelatinized and ungelatinized tapioca starch. These pearls are used in different dishes due to their unique transparent and chewy texture. They are produced through a process of wetting tapioca starch, forming spherical particles, and subjecting them to dry heat processing.

- Thickener and Stabilizer: It contributes to the texture and stability of food products without adding any flavor, allowing the natural flavors of the food to stand out.

- Modified Tapioca Starch: Chemical modifications of tapioca starch have resulted in specialized products that enhance the functionality and value of foods. These are used mostly in different chinese dishes, soups, etc

- Baby Food: Tapioca starch is a preferred choice in baby food formulations due to its texture, stability, and low flavor contribution. Modified tapioca starches may be used to enhance the physical properties of baby food products without undergoing chemical modifications.

- Asian-style Noodles: It helps improve the clarity and texture of noodle products and aids in water uptake during cooking, resulting in noodles with desirable texture and mouthfeel.

- Dextrinization: Tapioca starch is easily dextrinized, a process that involves breaking down starch molecules into smaller dextrin molecules. Tapioca dextrins offer advantages in stability and color due to the absence of lipids, making them suitable for various food applications despite the shift towards other starch sources in industrial dextrin production.

References:

Breuninger, William F., Kuakoon Piyachomkwan, and Klanarong Sriroth. “Tapioca/cassava starch: production and use.” Starch. Academic Press, 2009. 541-568.

Hsieh, C. F., Liu, W., Whaley, J. K., & Shi, Y. C. (2019). Structure, properties, and potential applications of waxy tapioca starches–A review. Trends in Food Science & Technology, 83, 225-234.